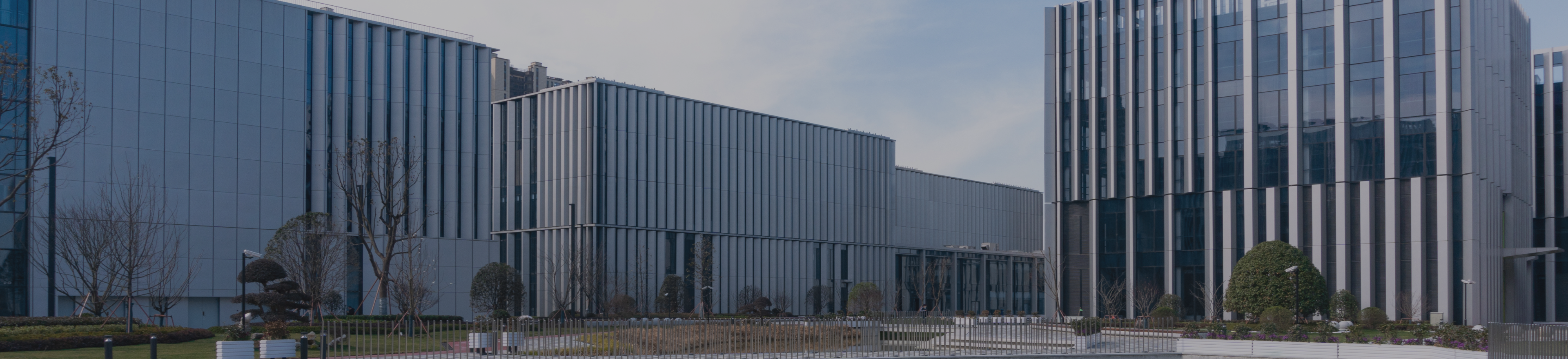

XF series medium-sized conveyors, in addition to the characteristics of general light suspension conveyors, also have the advantages of single point lifting capacity of 50-150kg, smooth operation, detachable chains, and good track stiffness. And it is widely used in many industries. Cross chain: WF-400 cross conveyor chain is suitable for traction on automobile wheel hub accumulation conveyors.

The chain is driven by the driving chain and runs continuously in the track. It plays the role of suspension and transmission in the conveyor. The conveyor chain is bidirectionally articulated, so in addition to linear motion, it can also follow the movement of the track. Curved shape, completing spatial curvilinear motion in horizontal and vertical planes.

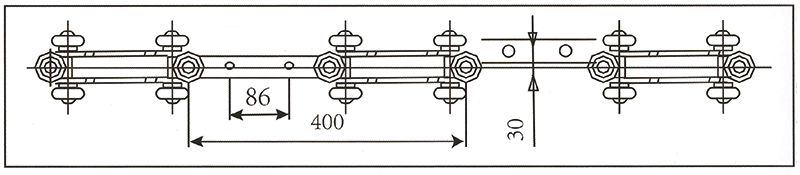

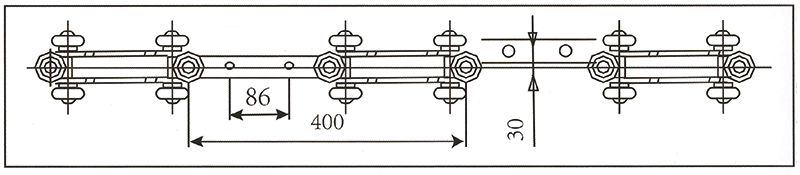

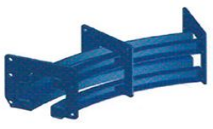

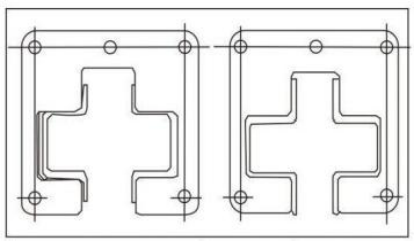

The figure below shows a simplified diagram of the conveyor chain of the XF series conveyor. Each section (T) has 4 running wheels, 4 guides and 2 cross sections. The running wheel and the guide wheel are connected by double chain plates through cross joints and pins. After the detachable hanging plate or fixed hanging plate is hung in the middle of the pin shaft, the workpiece can be transported. Their running wheels and guide wheels both adopt double-row ball structures, and their sizes are generally φ38 and φ45 bearings as guides and running wheels, and the track width is adjusted accordingly.

Product composition

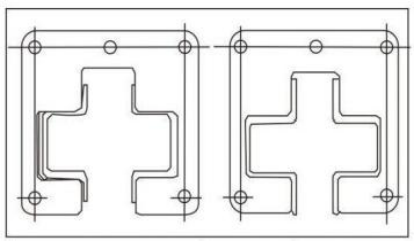

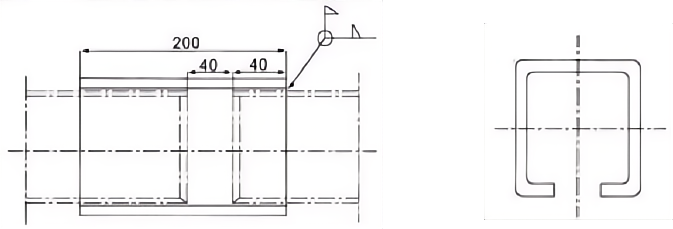

Track

The track consists of 3.5mm, 4mm, 5mm, 6mm.In four specifications of steel plates, horizontal and vertical curved rails generally use 3.5mm, 4mm, and 5mm.In four specifications of 6mm steel plates. Under harsh working conditions and high line tension, the load-bearing side guide rails in horizontal and vertical curved rails can be made of 45 square steel, which is durable.

XF400 Standard straight rail XF400 Horizontal curved rail

XF400 Vertical (upper arch) curved rail XF400 Vertical (lower curved) curved rail

Track structure diagram

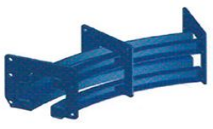

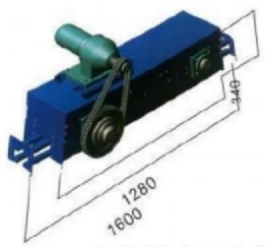

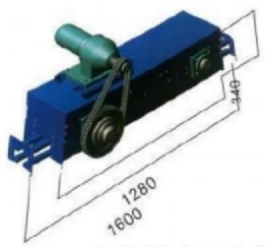

Drive device

The drive device of the XF400 series conveyor adopts a caterpillar chain linear drive method, ensuring safe and stable operation with minimal noise. To prevent damage to the drive device in case of a fault along the entire line, a torque limiter is also equipped. This ensures that the entire system can stop promptly when a fault occurs, protecting the various components of the conveyor system from damage.

The drive device of the XF400 series conveyor

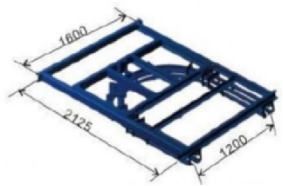

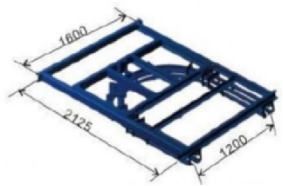

Tensioning devices come in various forms such as spring tensioning, weight tensioning, and pneumatic tensioning. During operation, the floating frame of the tensioning device is supported by four U-shaped bearings, allowing it to move flexibly back and forth on a fixed frame made of channel steel. The standard radius of the tensioning device is 600 millimeters, and the standard tensioning stroke is 400 millimeters;special dimensions can be manufactured according to customer requirements.

The tensioning device of the XF400 series conveyor

Bracing

The bracing plays the role of carrying the workpiece during the operation of the equipment. It is a tool used to support the workpiece.

Working principle

The motor drives the reducer. The reducer drives the sprocket to rotate. The sprocket meshes with the cross chain. Thus, the chain moves circularly on the frame. Materials are placed on the chain and are conveyed to the designated position as the chain moves.

EN

EN