Product Specification

|

Type

Project

|

QXT-150

|

QXT-200

QXT-206

|

QXT-240

QXT-250

|

QXT-300

|

|

Pitch of chain links mm

|

150

|

200/206

|

240/250

|

300

|

|

Single point suspended load kg

|

8

|

30

|

50

|

120

|

|

Allowable tensile force of chain KN

|

2.5

|

3

|

5

|

10

|

|

Breaking tensile force of chain KN

|

≥2.5

|

≥30

|

≥50

|

≥100

|

|

Chain weight kg/m

|

2.83

|

5.2/5.1

|

7.6/7.9

|

13

|

|

Track weight kg/m

|

4.36

|

7.18

|

8.12

|

14.6

|

|

Operating speed m/min

|

0.26~2.6

0.52~5.2

0.87~8.7

1.21~12.1

1.51~15.1

|

1.18~1.8

0.25~2.5

0.36~3.6

0.51~5.1

0.62~6.2

0.88~8.8

|

0.34~3.4

0.5~5

0.7~7

1.12~11.2

|

0.2~2

0.3~3

0.41~4.1

0.61~6.1

1.04~10.4

|

|

Speed variation range

|

1:10 stepless

|

1:10 stepless

|

1:10 stepless

|

1:10 stepless

|

|

Operating temperature ℃

|

-20~200

|

-20~200

|

-20~200

|

-20~200

|

|

Conveyor power KW

|

0.75/1.1

|

1.1/1.5

|

1.5/2.2

|

3

|

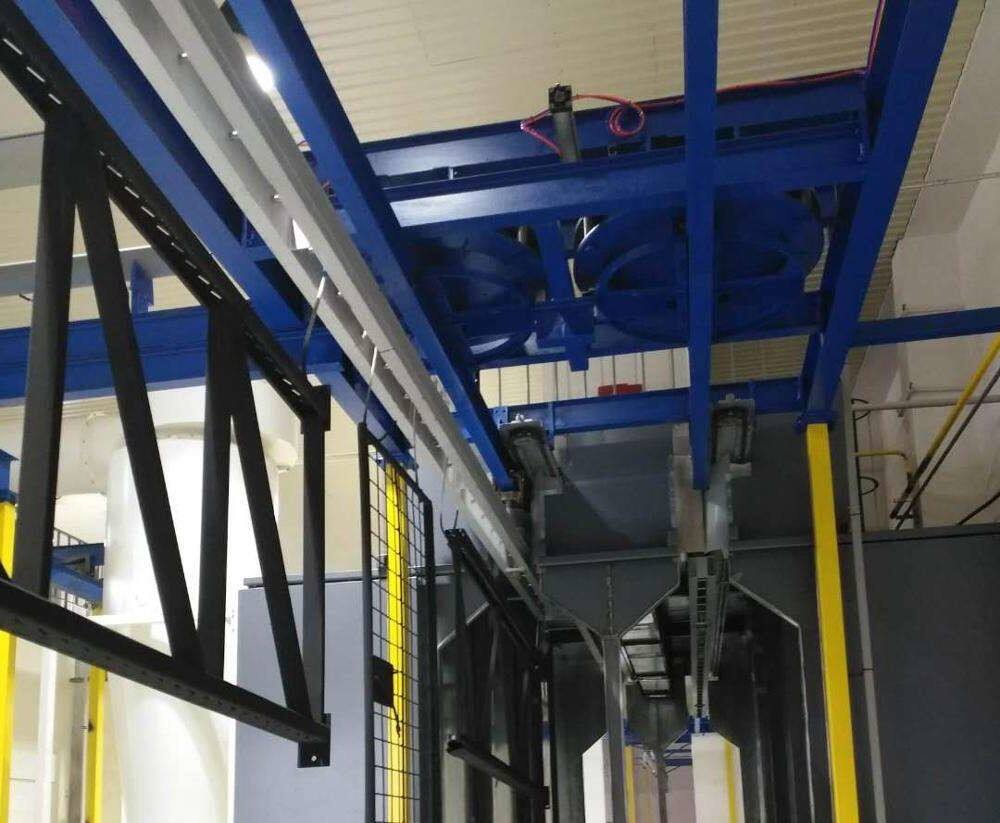

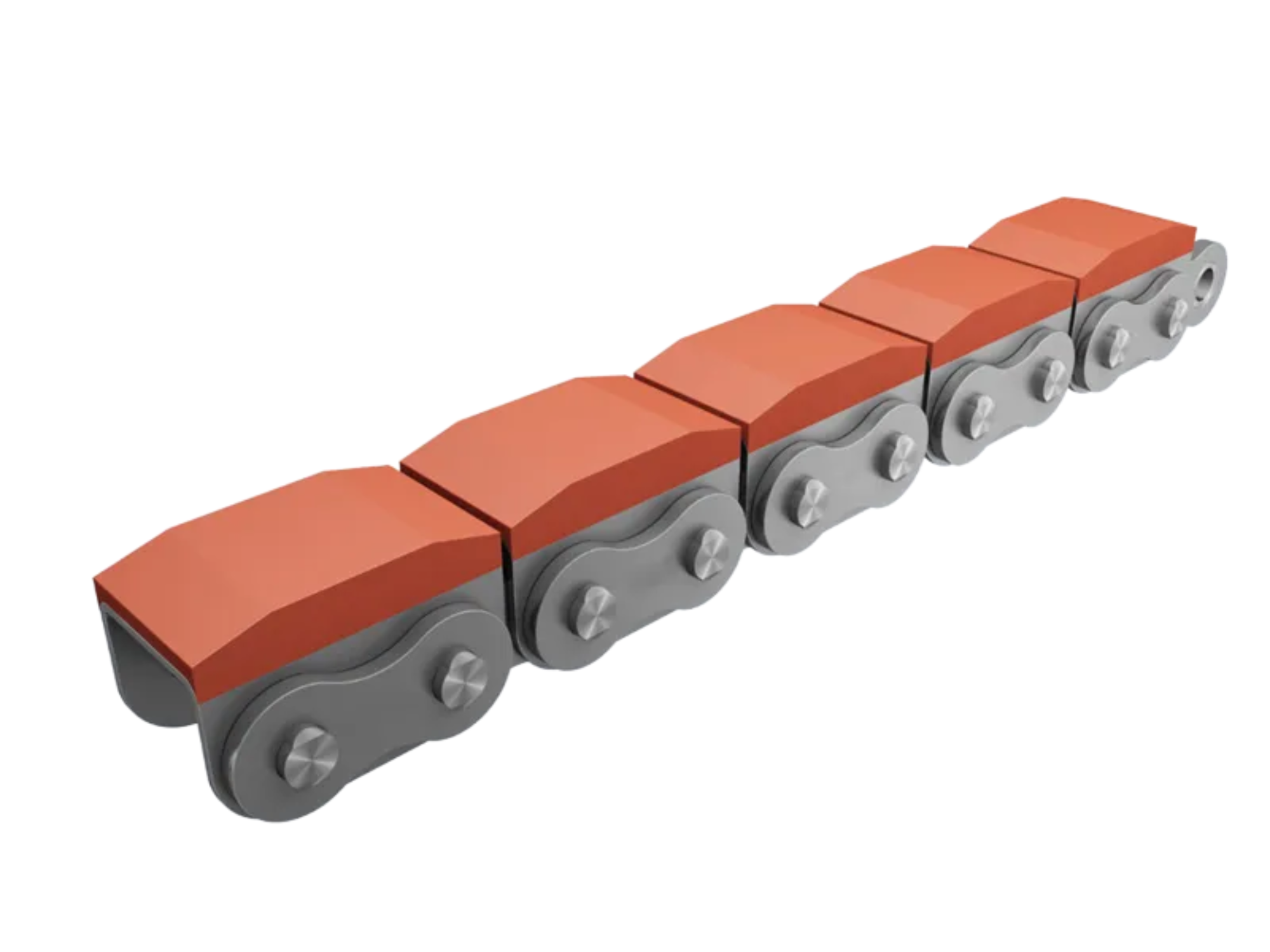

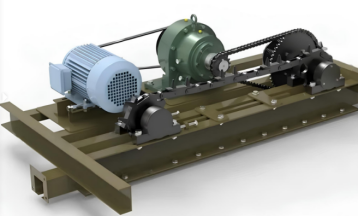

Product composition

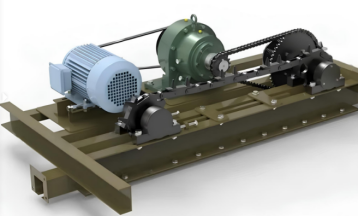

Drive unit

The power of the driving device is transmitted to the cycloidal pinwheel reducer through the belt through the adjusting motor, and then from the reducer to the driving spindle through the chain sprocket. Finally, the driving wheel directly drives the conveyor chain to move in the closed rail cavity to transport suspended objects forward. When a fault occurs during operation and the traction force is overloaded, the adjustable safety clutch set on the drive device immediately automatically disengages, and at the same time, its movable half-clutch presses the electrical travel switch, causing the motor to stop and the entire line to stop running. After the fault is eliminated, re-engage the clutch end face. At this time, the engine can be started and run normally without any adjustment.

|

Project

Type

|

A1

|

A2

|

L1

|

L2

|

L3

|

H1

|

H2

|

|

QXT-150

|

618

|

74

|

1600

|

1440

|

231

|

443

|

127

|

|

QXT-200、206

|

600

|

80

|

1800

|

1600

|

231

|

494

|

148

|

|

QXT-240、250

|

612

|

94

|

1950

|

1750

|

248

|

538

|

180

|

|

QXT-300

|

740

|

110

|

2200

|

2000

|

277

|

615

|

240

|

Straight rail

It is used for the conveyor chain to run horizontally and straightly. The standard length is 6 meters. It can be cut to any length according to the installation site conditions.

|

Type

|

A

|

B

|

C

|

a

|

|

QXT-150

|

54

|

47

|

19

|

3.5

|

|

QXT-200、206

|

72

|

68

|

26

|

4

|

|

QXT-240、250

|

80

|

80

|

25

|

4

|

|

QXT-300

|

100

|

100

|

32

|

5

|

Horizontal curves

Used for horizontal turns of conveyor chains, with standard radius R500mm~R1000mm×180°. It can be cut to any degree according to the installation site conditions. Horizontal elbows can also be customized and processed according to customer needs.

|

Type

|

R

|

n

|

|

QXT-150

|

500、600

|

30、45、90、180

|

|

QXT-200 206

|

600、800

|

30、45、90、180

|

|

QXT-240 250

|

800、1000

|

30、45、90、180

|

|

QXT-300

|

800、1000

|

30、45、90、180

|

Take-up assembly

The function of the tensioning device is to maintain a relatively stable tensioning force on the entire conveyor chain during operation, and at the same time, it can absorb or compensate for the expansion and contraction of the conveyor chain due to thermal expansion, contraction and deformation caused by force during operation.

|

Project

Type

|

R

|

L

|

L1

|

L2

|

H

|

S

|

|

QXT-150

|

500、600

|

1680、1780

|

600、800

|

150

|

47

|

300

|

|

QXT-200、206

|

600、800

|

1780、1980

|

800、1200

|

150

|

68

|

300

|

|

QXT-240、250

|

800、1000

|

1780、1980

|

1200、1600

|

150

|

80

|

300

|

|

QXT-300

|

800、1000

|

1980、2180

|

1200、1600

|

150

|

100

|

300

|

Upper arch and lower curved rail

It is used for the rising and falling parts of the conveyor chain. It can be cut at any angle according to the installation site conditions, but the angle should not be greater than 45°. At the same time, the influence of the distance between the two neighboring spreaders on the rising and falling sides should be considered.

|

Type

|

R

|

α°

|

|

QXT-150

|

500、600

|

30°、45°

|

|

QXT-200、206

|

600、800

|

30°、45°

|

|

QXT-240、250

|

800、1000

|

30°、45°

|

|

QXT-300

|

800、1000

|

30°、45°

|

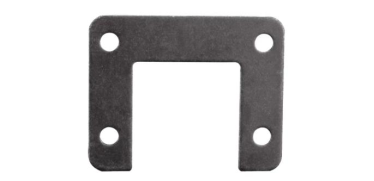

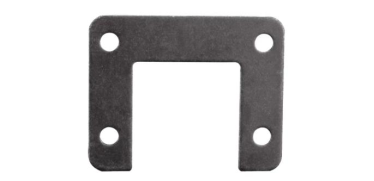

Bracket

Bracket is the most commonly used connection method between rails. When using bracket connection, you only need to weld a bracket on both ends of the two rails to be connected to each other, and then bolt the two brackets together. Just connect them.

|

Type

|

A

|

B

|

C

|

D

|

δ

|

φd

|

|

QXT-150

|

55

|

47

|

105

|

70

|

4

|

11

|

|

QXT-200 206

|

73

|

68

|

134

|

105

|

4

|

11

|

|

QXT-240 250

|

81

|

80

|

140

|

110

|

5

|

11

|

|

QXT-300

|

101

|

100

|

165

|

135

|

8

|

14

|

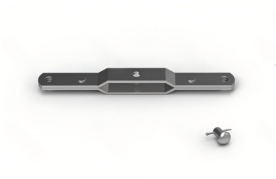

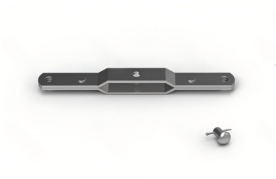

Hanger plate

A lifting plate is a component that connects to the conveyor chain on one end and to the suspended item on the other. Lifting plates can be categorized into two types: fixed and detachable. The QXT-240 and QXT-250 models utilize fixed lifting plates that are permanently attached to the conveyor chain. All other lifting plates are of the detachable variety. Detachable lifting plates come in three structural designs: standard, Y-type, and beam-style.

|

Hanger plate type

Type

|

Standard

|

Y-type

|

Beam-style

|

|

L

|

d

|

B

|

b

|

L

|

d

|

A

|

B

|

b

|

L

|

d

|

A

|

B

|

b

|

|

QXT-150

|

Hanger plate type

|

88

|

8

|

16

|

10

|

221

|

8.5

|

150

|

16

|

10

|

88

|

10

|

150

|

20

|

14

|

|

Allowable hanger weight

|

8kg

|

8kg

|

15kg

|

|

QXT-200

|

Hanger plate dimensions

|

120

|

8.5

|

18

|

10

|

234

|

8.5

|

200

|

18

|

12

|

120

|

12

|

200

|

18

|

10

|

|

Allowable hanger weight

|

30kg

|

30kg

|

55kg

|

|

QXT-250

|

Hanger plate dimensions

|

120

|

10.5

|

20

|

12

|

|

|

|

|

|

110

|

14.5

|

250

|

20

|

12

|

|

Allowable hanger weight

|

50kg

|

|

90kg

|

|

QXT-300

|

Hanger plate dimensions

|

130

|

12.5

|

27

|

15

|

|

|

|

|

|

130

|

16.5

|

300

|

27

|

15

|

|

Allowable hanger weight

|

100kg

|

|

180kg

|

|

Maximum hanger angle

|

45°

|

90°

|

45°

|

Return idler horizontal curve

When a suspended conveyor chain requires a 180° horizontal turn and a smaller turning radius is desired, a swivel assembly can be used as an alternative to horizontal curved tracks.

|

Project

Type

|

R

|

B

|

H

|

H1

|

|

QXT-150

|

200

|

454

|

170

|

94

|

|

250

|

554

|

170

|

94

|

|

300

|

654

|

170

|

94

|

|

350

|

750

|

170

|

94

|

|

QXT-200 206

|

250

|

572

|

180

|

115

|

|

300

|

672

|

180

|

115

|

|

350

|

772

|

180

|

115

|

|

400

|

872

|

180

|

115

|

|

QXT-240 250

|

400

|

880

|

268

|

155

|

|

450

|

980

|

268

|

155

|

|

500

|

1080

|

268

|

155

|

|

550

|

1180

|

268

|

155

|

|

600

|

1280

|

268

|

155

|

|

QXT-300

|

400

|

900

|

278

|

175

|

|

450

|

1000

|

278

|

175

|

|

500

|

1100

|

278

|

175

|

|

550

|

1200

|

278

|

175

|

|

600

|

1300

|

278

|

175

|

Track hanger clamp

An installation bracket is a mounting component used to clamp the conveyor track during the installation of a conveyor line.

|

Type

|

H

|

h

|

d

|

B

|

d

|

a

|

S

|

|

QXT-150

|

100

|

84

|

10

|

60

|

30

|

5

|

8

|

|

QXT-200、206

|

120

|

104

|

10

|

60

|

30

|

5

|

8

|

|

QXT-240、250

|

147

|

122

|

12

|

110

|

60

|

6

|

8

|

|

QXT-300

|

167

|

142

|

12

|

130

|

80

|

6

|

8

|

Furnace suspension

When the operating track passes through high-temperature areas such as baking, temperature expansion joints should be installed at both ends of the high-temperature section. One end of the temperature expansion joint should be welded to the track, and the other end should have a sliding sleeve that connects with another track. An appropriate gap should be maintained between the two tracks to allow for thermal expansion and deformation.

|

Type

|

QXT-150

|

QXT-200260

|

QXT-240250

|

QXT-300

|

|

L

|

100

|

120

|

160

|

160

|

|

B

|

100

|

120

|

124

|

168

|

|

φd

|

13

|

13

|

12

|

11

|

Track inspection section

There is a removable access window on the inspection track, through which the conveyor chain can be installed, removed, inspected, and maintained. Each conveyor line should be equipped with at least one set of inspection tracks, while longer ones may require 2-3 sets. These are typically located between the drive unit exit and the tensioning device, or in areas where the chain tension is lower and access to inspection and maintenance is convenient.

Sprocket rotator

8-Gear Rotating Suspension 20-Gear Rotating Suspension

Temperature expansion joint

When the operating track passes through high-temperature areas such as baking, temperature expansion joints should be installed at both ends of the high-temperature section. One end of the temperature expansion joint should be welded to the track, and the other end should have a sliding sleeve. An appropriate gap should be maintained between the two tracks to compensate for thermal deformation.

EN

EN

AR

AR

HR

HR

BG

BG

FI

FI

NL

NL

DA

DA