I. Structure and Material

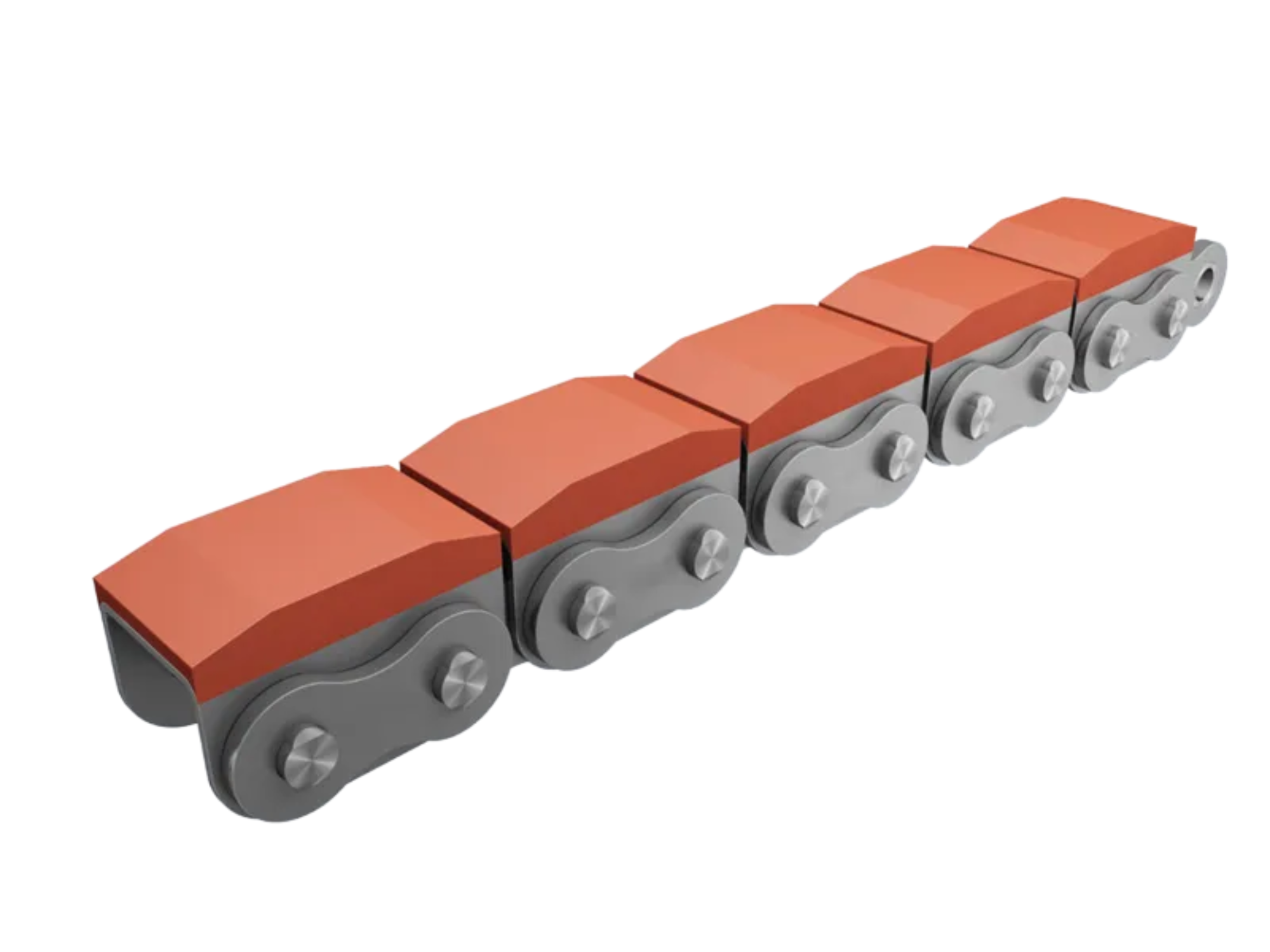

The chains used in ice cream filling production lines typically feature a robust construction. Composed of multiple interconnected link units, each unit consists of inner and outer link plates, pins, bushings, sleeves, and rollers. The inner and outer link plates, usually made of high-quality alloy steel or stainless steel, provide the necessary strength and rigidity to support the weight of ice cream products and endure the rigors of high-speed operation. The pins are precisely machined and fit snugly with the bushings, which are often crafted from wear-resistant engineering plastics like nylon. This combination minimizes friction and wear, enhancing the overall durability of the chain. The rollers, made of materials such as POM, ensure smooth movement along the sprockets, reducing noise and vibration during operation.

II. Performance Characteristics

These chains possess outstanding performance attributes. Their excellent wear resistance is achieved through advanced design features, such as the proper combination of bushings and precise clearances between components. This not only prolongs the service life of the chain but also significantly reduces the generation of iron filings, safeguarding the purity and quality of the ice cream. The chains are engineered to run smoothly and quietly, thanks to the well-designed roller and sprocket interaction. They can maintain stable operation even under the continuous and high-intensity demands of the filling process, ensuring accurate and consistent product conveyance. Additionally, their good corrosion resistance allows them to withstand the potentially corrosive environment in an ice cream production facility, including exposure to cold temperatures, moisture, and various food ingredients and additives.

III. Application Advantages

In the ice cream filling production line, these chains offer numerous application benefits. They are highly adaptable and can be customized to fit different types of filling equipment, whether it's a multi-head filler, cup filler, or cone filler, accommodating diverse production processes and capacities. By ensuring precise and stable transportation of ice cream products, they enhance production efficiency, minimizing production interruptions caused by misalignment or inconsistent conveyance. Moreover, the chains' ability to maintain a hygienic production environment by preventing the introduction of contaminants due to wear is crucial in the food industry. This not only meets strict quality and safety standards but also helps to build a positive brand image for ice cream manufacturers, ultimately contributing to the success and competitiveness of their products in the market.

EN

EN

AR

AR

HR

HR

BG

BG

FI

FI

NL

NL

DA

DA