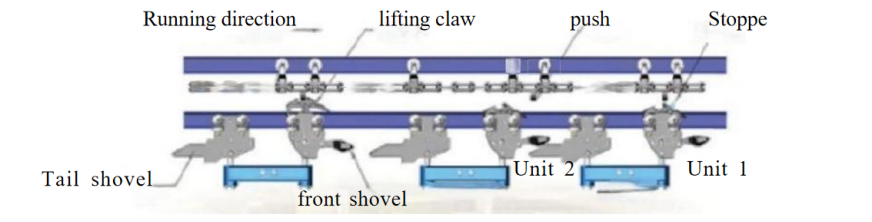

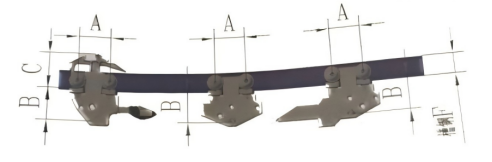

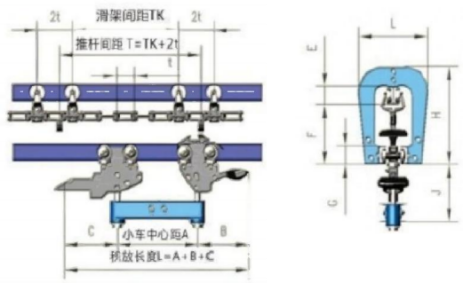

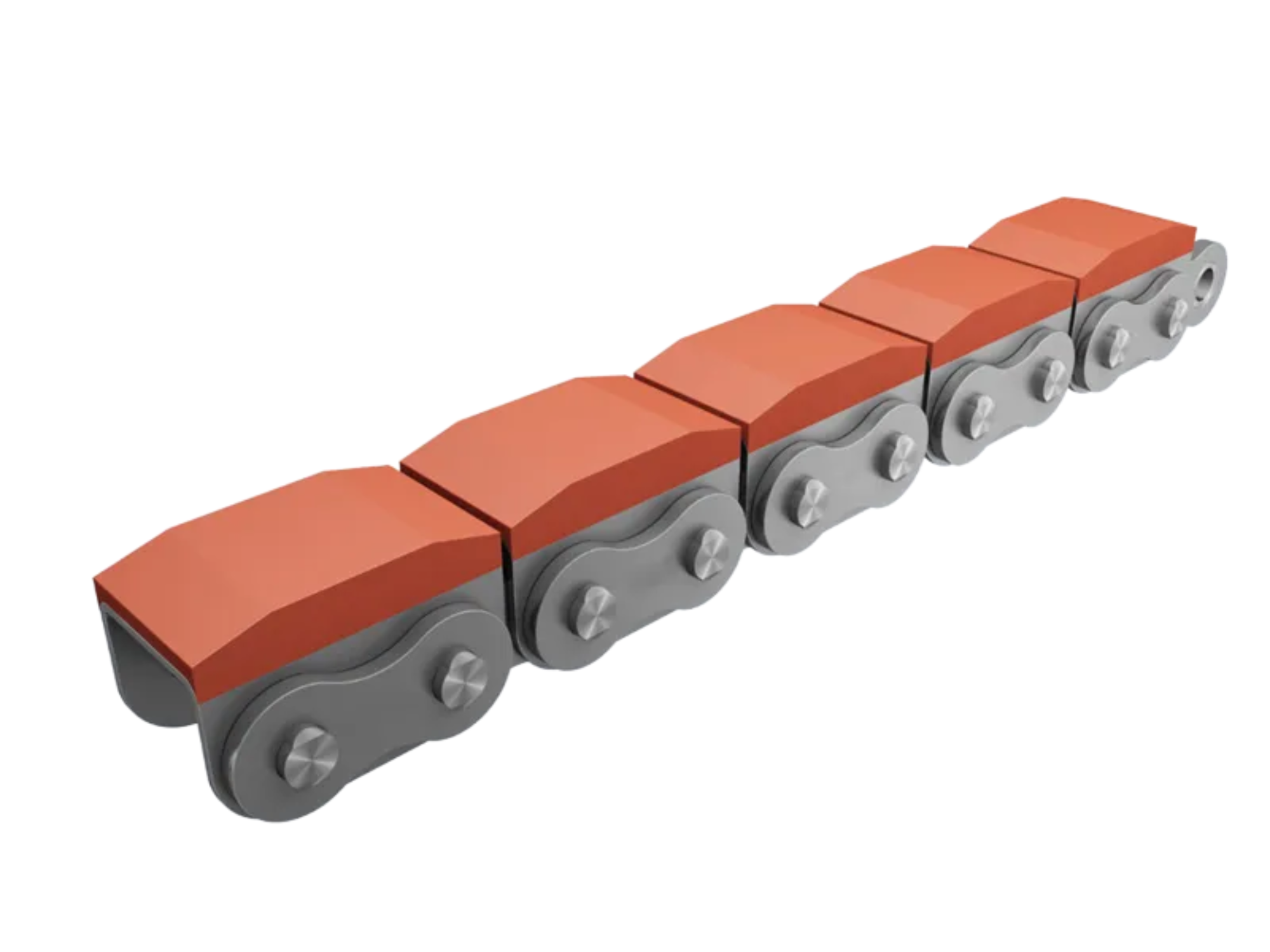

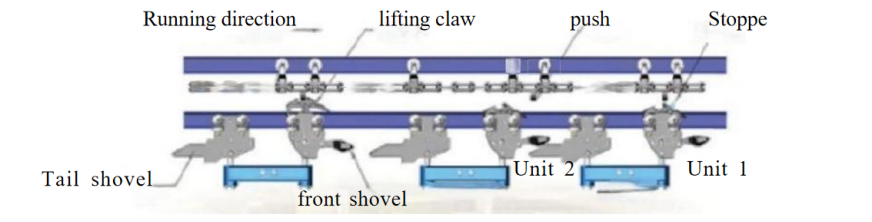

The power and free trolley set is generally composed of a front trolley, a rear trolley and a load beam. A front shovel is installed on the front trolley and connected to the lifting claw through a coupling mechanism. A tail shovel is installed on the rear trolley. When accumulation operation is required, the pneumatic stopper is opened, and the lifting claw on the front trolley of the first trolley set is pressed down to disengage it from the pusher on the traction chain, and the first trolley set stops running. The second trolley set continues to move forward until the front shovel of the front trolley rises along the inclined plane of the rear trolley of the first trolley set and drives the lifting claw to descend and disengage from the traction chain. The second trolley set stops running, and the same applies to subsequent trolley sets. When the accumulation operation is completed, the pneumatic stopper is closed. The lifting claw on the front trolley of the first trolley set is lifted by the weight of the front shovel itself. The pusher on the traction chain is in place to push the first trolley set to move forward. As the first trolley set moves forward, the front shovel of the front trolley of the second trolley set is disengaged from the tail shovel of the rear trolley of the first trolley set, and the lifting claw is lifted to complete the accumulation operation.

EN

EN

AR

AR

HR

HR

BG

BG

FI

FI

NL

NL

DA

DA